Perhaps you happened upon a piece of latex in our Clearance section that is just about the right size for your projects or maybe you have an old couch made of latex that you are ready to part with but you realize there is still life left in the foam, so you get creative. Your new project could use some natural latex but you want to save a few dollars by cutting it yourself and not paying us to cut it. Here is how you DIY a latex cut.

SUPPLIES:

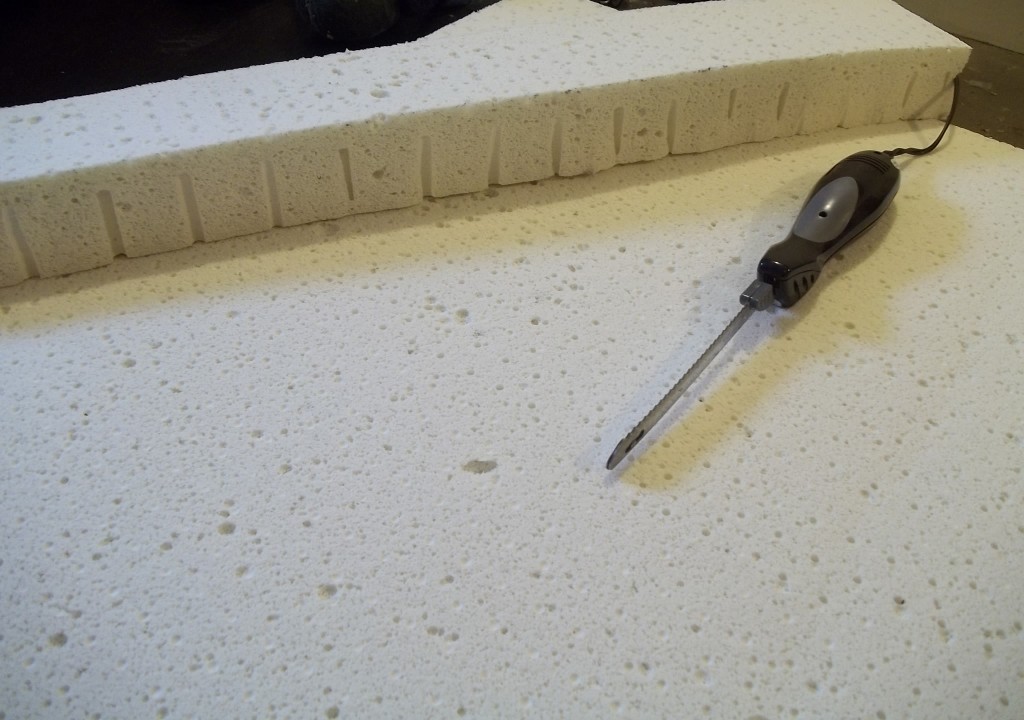

- Electric Knife

- Two Tables the same Height

- Your Natural Latex Slab

TECHNIQUE:

The best tip I can give you is to use a slow, steady hand, not pulling the latex apart as you cut, but letting it sit still.

- Draw your cut on the latex with an extra fine tip permanent marker and a yardstick or an upside down tape measure. Make sure your line is straight as you will be watching it very closely when you are cutting. Do not draw your line according to the pinholes on the latex as they do not always line up vertically and horizontally to the edges of the latex. Rather measure from the actual edges of the latex.

- Place your two tables next to each order with a 5″ or so gap between them. Place the latex on the tables with the cut line in the space between the tables.

- An optional step, but perhaps beneficial step is lubricating your blades. If you have a silicone spray lubricant around, spray both sides of the blades to provide an easy cut.

- Position yourself in a comfortable position, accessible to the cut. Depending on how large your piece is, you may find it easiest to cut the latex if you crawl on top of it. If you do so, make sure your knees are not pulling on the area of latex around the cut.

- Position the cord of your knife so that it is not in your way as you move backward along the cut or in the cut’s way.

- Align your knife on the line, turn the blades on and very slowly, cut down your line. It is easiest to pull the knife toward you rather than to push it away from you. Keep your knife hand over the line so that you do not end up with a cut inches to the side of the line on the bottom of the piece. If you need to shift your position, turn the knife off first, adjust and resume. Do not stretch the latex when cutting. It is a very flexible foam and stretching or pulling it during your cutting will give you a wobbly cut line. The holes in the latex may give you a slightly wobbly drawn line; you may have to eyeball a straight line from each hole.

- Just like when you cut wood and leave behind sawdust, there will be a little shredded latex on the ground to sweep up.

Of course, if after reading this you have changed your mind about DIYing your cut, give us a call and we’ll cut it for you. To get a quote on a custom cut piece of latex, visit our Custom Cut Latex Calculator.

Happy DIYing.